What Is an Industrial Panel PC? Key Benefits and Use Cases

In industries where performance, reliability, and resilience are non-negotiable, a traditional desktop or tablet just won’t do. That’s where industrial panel PCs come in—a category of rugged, all-in-one computing systems built to survive and thrive in the world’s harshest environments.

From manufacturing plants and retail kiosks to logistics hubs and smart buildings, industrial panel PCs are quietly powering automation, control, and information systems around the globe. But what exactly is an industrial panel PC, what makes it different, and why are so many companies adopting them?

This comprehensive guide explains everything you need to know—plus how solutions from ShiMeta Devices can help meet your deployment needs.

What Is an Industrial Panel PC?

An industrial panel PC is an integrated computing system that combines a touchscreen display, embedded motherboard, and sealed enclosure into a compact, durable unit. Designed specifically for commercial and industrial use, these systems offer superior reliability, configurability, and longevity compared to consumer-grade computers.

🧩 Key Features:

- Touch panel (resistive or capacitive)

- Fanless cooling for silent operation

- Wide operating temperature range

- Industrial-grade I/O ports (RS232, RS485, GPIO, LAN, USB)

- Mounting options (VESA, panel, wall, DIN rail)

- Support for Android, Linux, or Windows OS

Industrial panel PCs are built to work continuously in environments where dust, moisture, vibration, or extreme temperatures are common.

How Does It Differ from Consumer Devices?

Unlike regular PCs or tablets, industrial panel PCs are:

| Feature | Consumer Devices | Industrial Panel PCs |

| Build Quality | Plastic chassis | Rugged aluminum or steel housing |

| Operating Time | Intermittent | 24/7 continuous use |

| Cooling System | Fan-based | Fanless heat dissipation |

| Environmental Tolerance | Indoor only | Wide temperature & humidity ranges |

| I/O Interfaces | Limited (USB, HDMI) | RS232, RS485, CAN, GPIO, LAN |

| Lifecycle | Short (1–2 years) | Long-term (5+ years) availability |

| OS Flexibility | Locked ecosystems | Fully customizable |

Key Benefits of Using an Industrial Panel PC

✅ 1. Ruggedized for Harsh Environments

Industrial panel PCs are built with tough materials and sealed enclosures (IP65, IP67 ratings) to withstand:

- High dust environments (e.g., factories, mines)

- Temperature extremes (−20°C to +60°C or wider)

- Vibrations from heavy machinery

- Moisture, oil, and chemical exposure

This durability ensures long-term reliability, even in the most demanding applications.

✅ 2. Fanless and Maintenance-Free

Thanks to advanced heat dissipation design, most industrial panel PCs are fanless, which means:

- Silent operation (ideal for retail or healthcare)

- Fewer moving parts = fewer failure points

- Lower maintenance costs over time

For example, ShiMeta’s fanless panel PCs use aluminum alloy casings with passive heat sinks to ensure stability.

✅ 3. All-in-One Compact Design

Because the screen and computer are integrated, panel PCs:

- Save space on production lines or kiosks

- Reduce cabling complexity

- Make installation easier and faster

This is especially useful in environments with limited mounting space.

✅ 4. Mounting Flexibility

Depending on your deployment needs, you can install industrial panel PCs via:

- VESA mounts

- Panel mounts (flush into cabinets or walls)

- Arm mounts for mobile or adjustable positions

- DIN rail options for electrical cabinets

✅ 5. Broad OS Compatibility

Unlike most consumer devices, industrial panel PCs support:

- Android for smart displays and lightweight HMI

- Linux (Ubuntu/Debian) for industrial control and secure applications

- Windows 10/11 IoT Enterprise for compatibility with traditional software systems

This flexibility ensures integration with modern or legacy infrastructure.

✅ 6. Customizable I/O and Interfaces

Industrial workloads demand robust connectivity. Most panel PCs come equipped with:

- Serial ports: RS232, RS485

- USB: For peripherals like scanners and keyboards

- LAN/Ethernet: With optional PoE support

- GPIO/CAN: For machine control and automation systems

- Wi-Fi/4G/5G options: For cloud communication or mobile use

Popular Use Cases for Industrial Panel PCs

Industrial panel PCs are used across virtually every industry where performance and reliability are required.

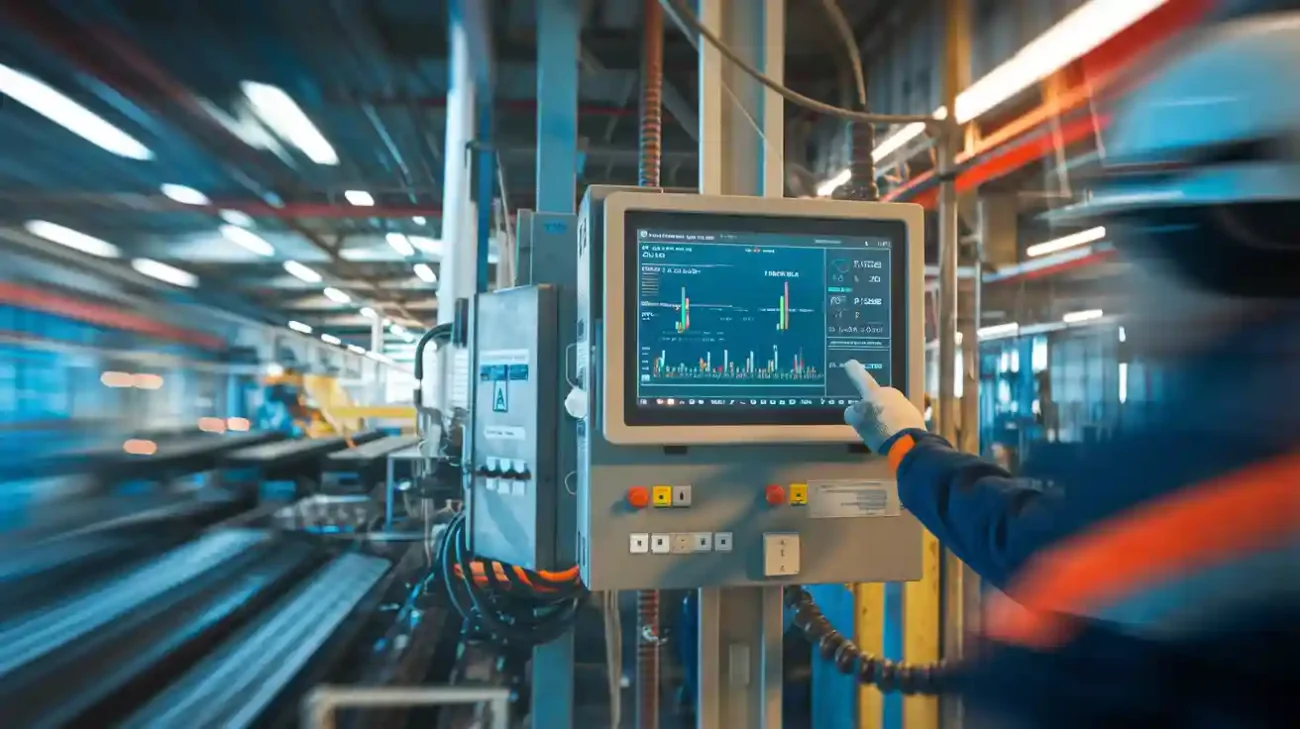

🏭 1. Human-Machine Interface (HMI) in Manufacturing

Panel PCs serve as HMI terminals on production lines, allowing operators to:

- Monitor process metrics

- Adjust machine settings

- View alarms or status notifications

- Interface with SCADA systems

With touchscreens, fanless design, and wide-voltage support, these systems withstand factory conditions while enabling real-time control.

🛍️ 2. Smart Retail & Self-Service Kiosks

In interactive environments, panel PCs power:

- Digital ordering stations

- Self-checkout terminals

- Product information kiosks

- Smart vending machine displays

Running on Android or Linux, they integrate easily with POS systems and cloud CMS platforms.

🚚 3. Logistics & Warehouse Automation

Mounted in forklifts, packing stations, or sorting hubs, panel PCs help logistics operators:

- Track shipments

- Scan barcodes

- Manage inventory

- Interface with ERP or WMS software

Features like glove-compatible touch, PoE, and rugged screens are critical for this use case.

🏥 4. Medical & Healthcare Devices

In hospitals and clinics, panel PCs are used for:

- Nurse station terminals

- Patient registration/check-in

- EMR access points

- Telehealth stations

IP65 front panels and antimicrobial coatings make them suitable for cleanroom environments.

🚉 5. Transportation & Smart Cities

Industrial panel PCs are deployed in:

- Ticket vending machines

- Traffic control cabinets

- Public information displays

- EV charging stations and parking terminals

Outdoor-ready models with sunlight-readable screens and -30°C cold-start capability are often required.

🏢 6. Building Automation & Energy Management

Panel PCs serve as local control hubs for:

- HVAC management

- Security system monitoring

- Access control systems

- Smart lighting and energy dashboards

Wall-mounted Android or Linux-based models are ideal for BMS (building management systems).

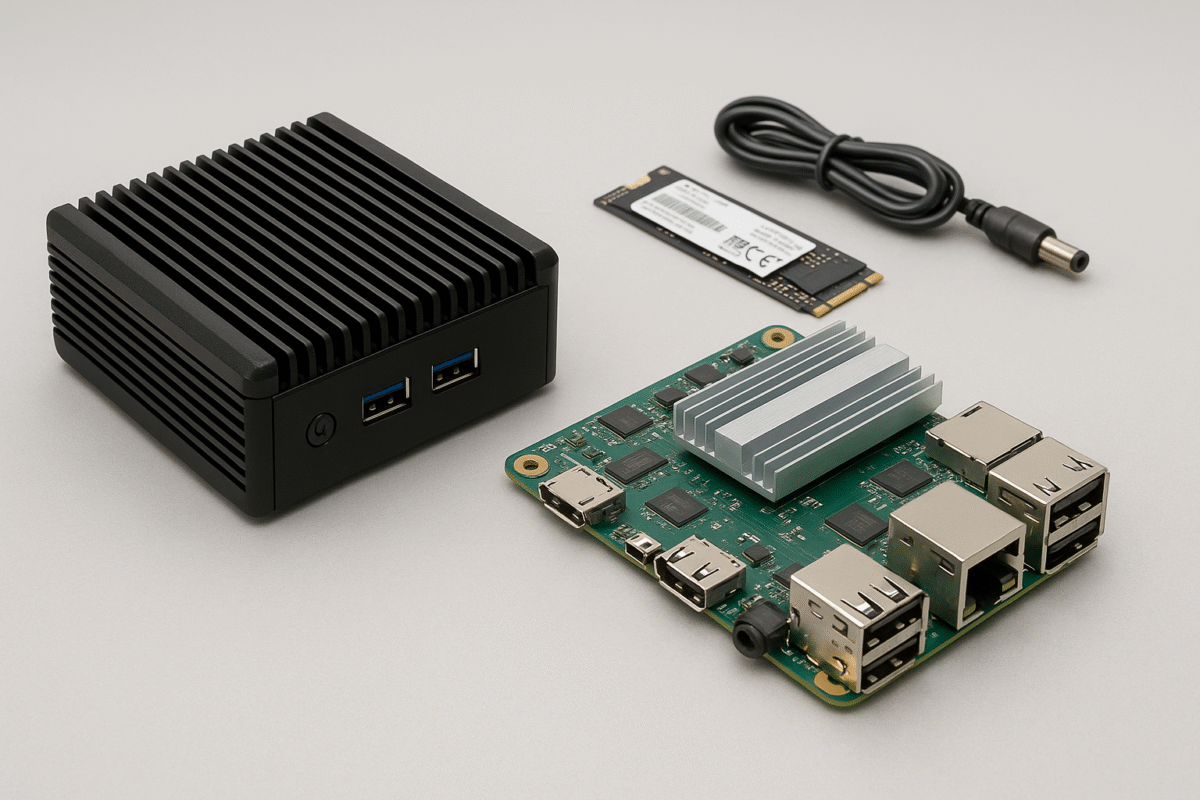

Why Choose ShiMeta Industrial Panel PCs?

At ShiMeta Devices, we engineer reliable, customizable, and high-performance panel PCs tailored for industrial and commercial use.

🔹 Android Panel PCs

- Based on RK3588, RK3568, or RK3399Pro

- Dual 4K video output

- 6 TOPS NPU for AI vision

- CMS compatibility for digital signage and HMI

🔹 Linux Embedded Panel PCs

- Fanless, PoE-powered

- GPIO and serial interface support

- Secure and long-lifecycle platform

- Ideal for automation and smart city deployments

🔹 x86 Windows Panel PCs

- Intel Atom, Celeron, or Core series

- Full Windows 10/11 IoT support

- Multi-display output

- Enterprise-grade SSD and RAM options

Quick Comparison Table

| Feature | ShiMeta RK3588 Panel PC | ShiMeta Linux Panel PC | ShiMeta x86 Panel PC |

| OS Support | Android 12 | Ubuntu/Debian | Windows 10/11 IoT |

| CPU Performance | 8-core Cortex-A76 | Quad-core ARM | Dual/Quad-core Intel |

| Display Sizes | 10.1″ – 21.5″ | 7″ – 15.6″ | 10.4″ – 19″ |

| Touchscreen | Capacitive (10-point) | Capacitive/Resistive | Capacitive |

| I/O Ports | HDMI, LAN, USB, RS232 | RS232/RS485, GPIO | HDMI, USB, LAN, COM |

| AI Support | 6 TOPS NPU | N/A | External GPU options |

| Best For | Retail, kiosks | Automation, smart city | Healthcare,enterprise |

Final Thoughts

Industrial panel PCs are essential tools in today’s smart manufacturing, logistics, and automation landscapes. They deliver:

- Rugged durability

- Long lifecycle and reduced TCO

- Flexible I/O and OS support

- Seamless integration into enterprise systems

Whether you’re deploying in a warehouse, kiosk, cleanroom, or control panel, choosing the right industrial panel PC can ensure your systems run smoothly, securely, and efficiently.