How to Maintain Your Industrial Panel PC for Long-Term Reliability

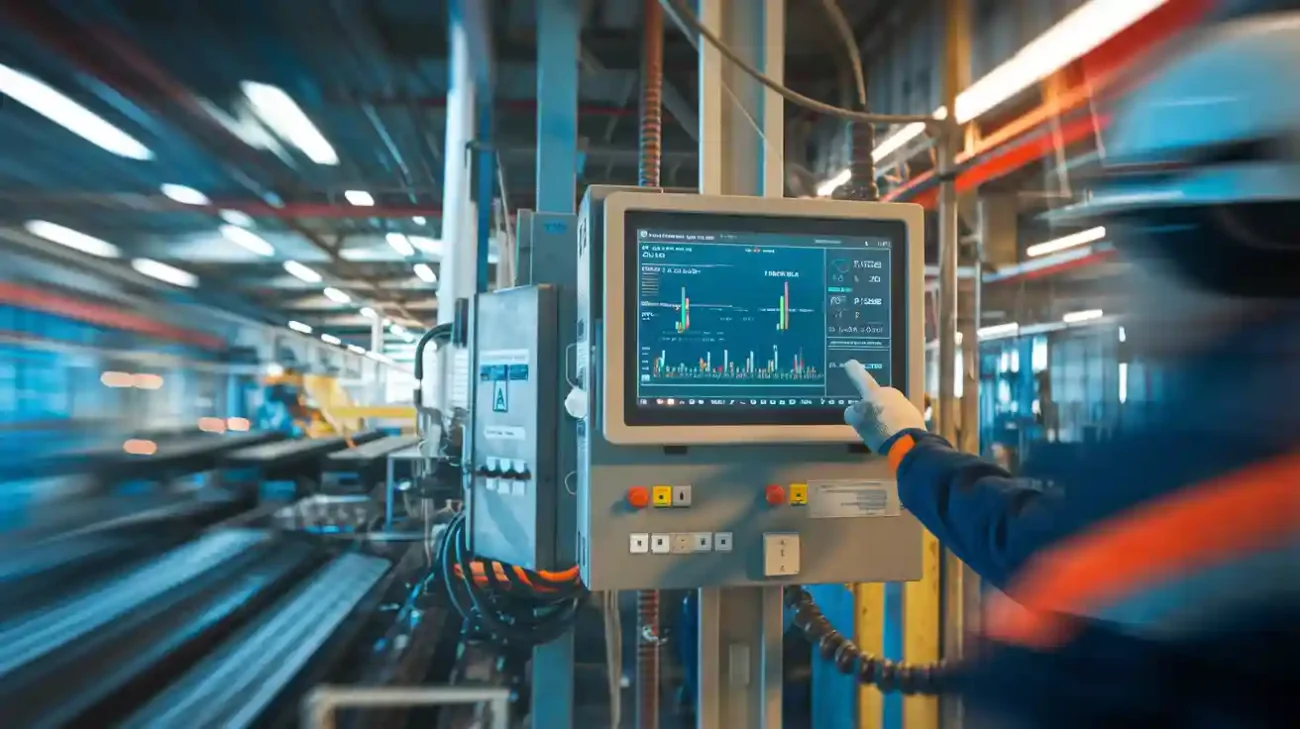

In the era of Industry 4.0, Industrial Panel PCs are no longer an optional extra, but have become essential tools for automating production plants, displaying real-time data, and controlling machines and industrial human-machine interface (HMI) systems. Whether installed directly on production lines, used in laboratories, or exposed to harsh outdoor conditions, these rugged computing devices can handle even the most demanding conditions.

However, even the most rugged tablets require regular maintenance. Neglecting proper maintenance leads to reduced performance and reliability, and even unexpected failures. In other words, careful maintenance of industrial tablets as important assets effectively reduces costly downtime, extends the life of the devices, and ultimately protects your investment in the long term.

This guide provides a comprehensive overview of basic industrial tablet maintenance practices, including routine checks, software updates, and environmental considerations. Mastering these practical strategies not only ensures consistent and stable system operation, but also enhances the reliability and safety of your equipment.

Why Maintenance Matters for Industrial Panel PCs

Industrial panel PCs operate in some of the harshest environments imaginable—dust, oil, moisture, shock, vibration, and high temperatures. Unlike office computers, these systems face:

- Continuous 24/7 use

- Exposure to contaminants

- Frequent user interaction (via touchscreen)

- Integration with machinery and external sensors

Without proper care, even rugged systems can experience performance degradation, hardware failure, or data loss. Maintenance is not just about avoiding breakdowns—it’s about ensuring safety, traceability, and efficiency on the factory floor.

Daily and Weekly Maintenance Tips

1. Visual Inspection

Check the physical condition of the panel PC regularly:

- Inspect for cracked screens, loose connectors, or damaged ports

- Ensure there are no foreign objects or buildup near ventilation slots or seals

- Confirm status LEDs (power, network, HDD) show normal operation

Visual inspection is a quick but effective way to catch early signs of trouble.

2. Touchscreen Cleaning

Use non-abrasive, anti-static cloths with approved disinfectants to clean the screen. Avoid:

- Harsh solvents like acetone

- Abrasive sponges or paper towels

- Spraying liquids directly onto the panel

Especially for capacitive touchscreens, improper cleaning can damage the sensor or reduce responsiveness.

3. Check Cabling and Mounts

- Ensure cables are securely fastened to avoid signal loss or intermittent power

- Inspect mounting brackets (VESA, arm, wall) for vibration, rust, or loose screws

- Replace damaged or frayed cables immediately

Monthly and Quarterly Maintenance Tasks

1. Monitor System Temperature

Use built-in monitoring tools or BIOS logs to track:

- CPU temperature

- Storage (SSD/HDD) health

- Overall system fan speeds (if present)

Overheating can drastically reduce component lifespan—even in fanless designs.

2. Clean Ventilation Paths

Even IP-rated devices can accumulate surface dust, which:

- Increases thermal load

- Blocks passive cooling channels

- May introduce particulate contamination in clean zones

Use compressed air to gently clean non-sealed ports or housings (if applicable).

3. Check Storage Health

For panel PCs with SSDs or HDDs, monitor for:

- SMART errors

- Bad sectors

- Read/write speed degradation

Use tools like smartctl (Linux) or CrystalDiskInfo (Windows). Consider replacing drives nearing end-of-life before failure.

Software and Firmware Maintenance

Maintaining software is just as critical as cleaning hardware.

1. OS and Firmware Updates

- Apply critical patches to Windows, Linux, or Android OS

- Update BIOS/UEFI and touch firmware when stability fixes are released

- Use LTS (Long-Term Support) builds to avoid frequent restarts in production environments

Tip: Schedule updates during planned downtime to avoid interruptions.

2. Backup and System Imaging

Maintain:

- Full disk images for fast recovery

- Backup of CMS/HMI/SCADA configurations

- Restore points in Windows or partition snapshots in Linux

This ensures business continuity in the event of failure or corruption.

3. Scan for Errors or Malware

Even air-gapped systems are vulnerable to:

- USB-borne threats

- Outdated software exploits

- Misconfigurations leading to instability

Regular security scans and audit logs protect both data and hardware.

Environmental Best Practices

1. Ensure Adequate Airflow

For fanless designs, natural airflow is critical. Avoid:

- Blocking vents or rear panels

- Installing the panel PC near heat-generating machinery

- Enclosing the unit in unventilated enclosures

Maintain clearance around the unit and consider heat sinks or heat-dissipating backplates if ambient temperatures are high.

2. Power Protection

Industrial environments often experience voltage fluctuations, which can cause:

- Data loss

- Power supply failure

- Motherboard damage

Use:

- Industrial-grade surge protectors

- Uninterruptible Power Supplies (UPS)

- Voltage regulators or PoE+ injectors for remote systems

3. Minimize Environmental Exposure

Avoid:

- Direct sunlight, which can overheat the display

- Constant exposure to oil mist, metal shavings, or vaporized chemicals

- Areas with poor grounding or static discharge risk

Choose IP65+ rated units for demanding conditions and use enclosure hoods for extra protection if needed.

Harsh Environment Maintenance Tips

1. Waterproofing & Seal Checks

In wet or washdown environments, inspect:

- IP65/IP66 gaskets for wear or damage

- Waterproof cable glands and seals

- Corrosion near screws, USB doors, or VESA mounts

Replace any degraded seals to avoid moisture ingress.

2. Disinfection in Cleanrooms and Labs

- Use alcohol-free, hospital-grade wipes to clean antimicrobial surfaces

- Maintain touchscreen clarity and avoid micro-scratches from aggressive scrubbing

- For medical or food-grade panel PCs, inspect for chemical discoloration or coating breakdown

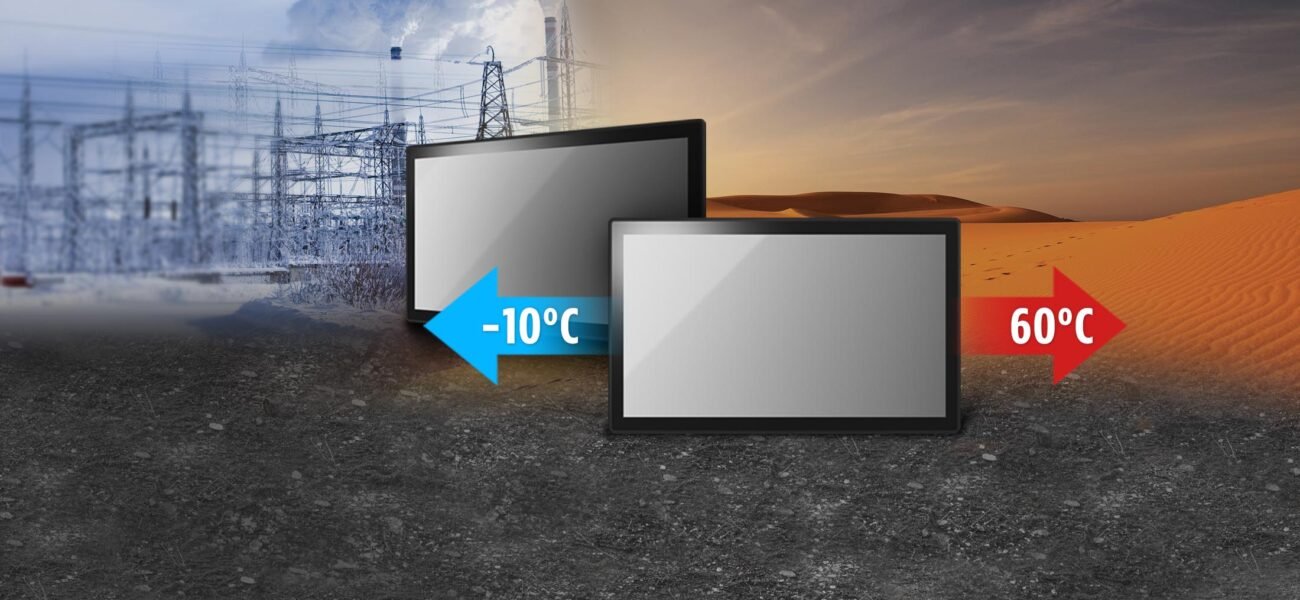

3. Condensation and Temperature Management

In cold storage or refrigerated warehouses:

- Ensure anti-condensation heaters are functional

- Allow gradual warm-up when moving from cold to warm zones

- Use humidity-resistant enclosures and coated motherboards

Pro tip: Use a wide-temperature fanless panel PC (–20°C to +60°C) for cold chain logistics.

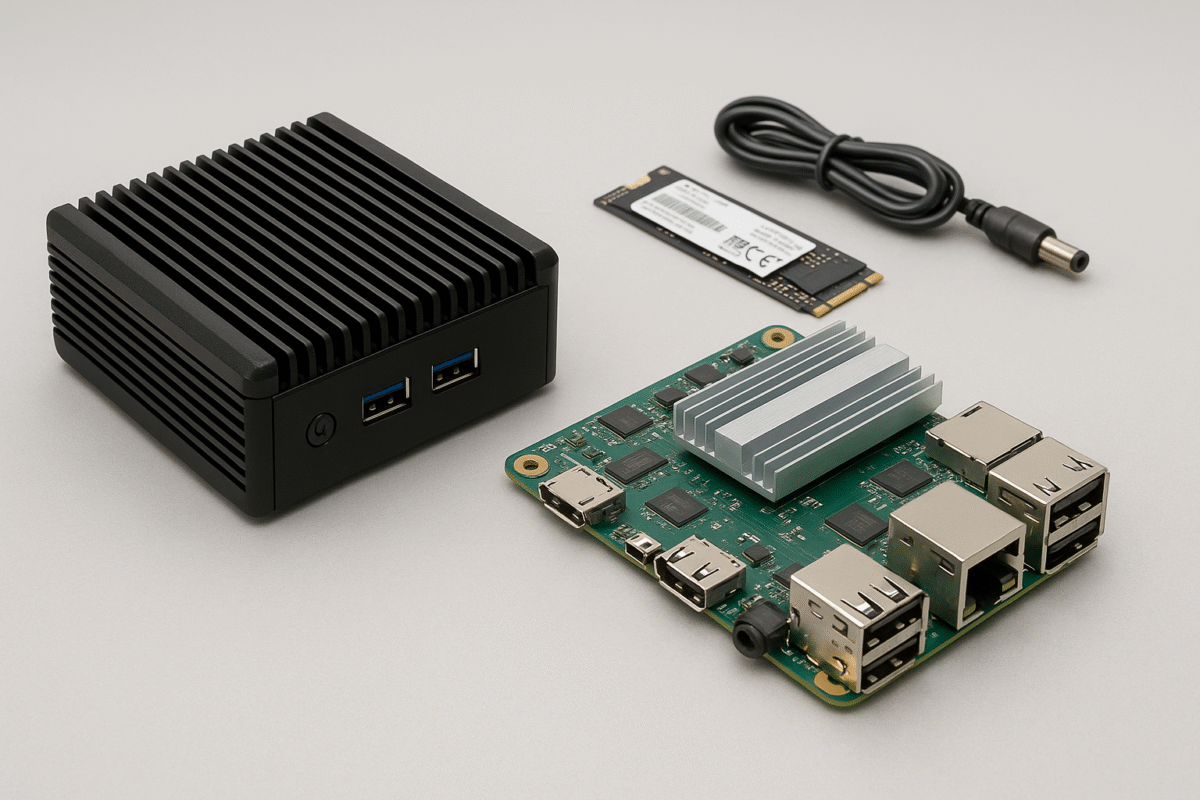

When and How to Replace Parts

Even with good maintenance, components have finite lifespans.

Replace:

- Touchscreens if they become unresponsive or cracked

- Storage devices showing write errors or reduced IOPS

- Motherboards after 5–7 years or if power issues persist

Ensure replacements are OEM-compatible and meet IP or EMC requirements.

ShiMeta Devices: Maintenance Support You Can Count On

At ShiMeta Device, we understand that industrial computing requires more than just great hardware — it demands reliable lifecycle support.

Our value-added services include:

Preventive Maintenance Schedules

- Remote Monitoring & Diagnostics

- Spare Parts Kits for Easy Replacement

- BIOS Locking and Firmware Updates

- Customized OS Builds for Long-Term Stability

Explore ShiMeta Industrial Panel PCs

📩 Contact Our Support Team

Conclusion: Maintain to Sustain

A rugged, fanless, industrial-grade panel PC can last 7–10+ years — but only if it’s properly maintained. Preventive maintenance is the most cost-effective insurance against:

- Costly downtime

- Emergency repairs

- Safety hazards in industrial zones

By following the best practices shared in this guide, you ensure your panel PCs remain stable, secure, and fully operational, delivering ROI for years to come.